4 metal surface treatments to know

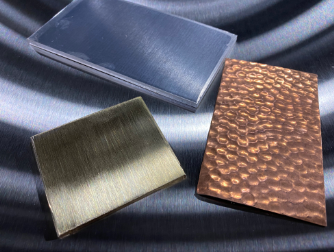

Metal surface treatments are used to finish metal in different ways and for different purposes. Commonly, they are chosen to withstand corrosion and wear and to apply an attractive finish. But they can also be used to deliver and enhance certain properties of the underlying surface, such as electromagnetism. The surface treatments can be applied to the entire product surface or just to certain sections.

Here are some of the main metal surface treatments to know.

1. Electroplating

This process works to create a thin and metallic coating on the metal substrate. It works by passing an electrical current, which is positively charged, through a solution that holds dissolved metallic ions. At the same time, a negatively charged electrical current is passed through the metallic element to be plated.

Metals typically used for this include chromium, cadmium, silver, copper, tin, zinc and nickel. Most base metals with the ability to conduct electricity can be electroplated in this way to boost their performance.

2. Electroless Plating

This is a method akin to electroplating, but it doesn’t use electricity. Instead, a reduction agent is used which sits directly in the plating solution. The result, carried out by experts such as https://www.poeton.co.uk/standard-treatments/, is broadly the same.

3. Chemical treatment

This method uses different chemical treatments and processes that place thin films of oxide and sulphide on the surface. These are often used to provide protection against corrosion, to colour metal and to prime a surface before painting it. The most common surface treatment for steel is black oxide.

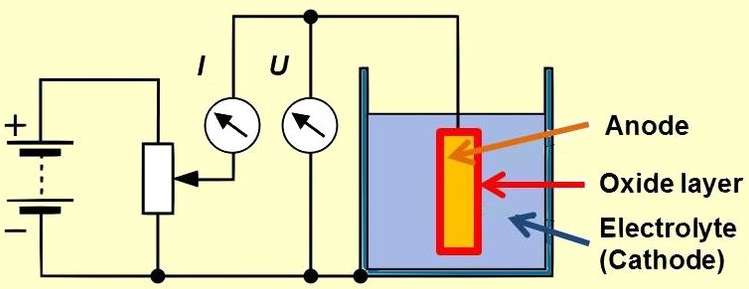

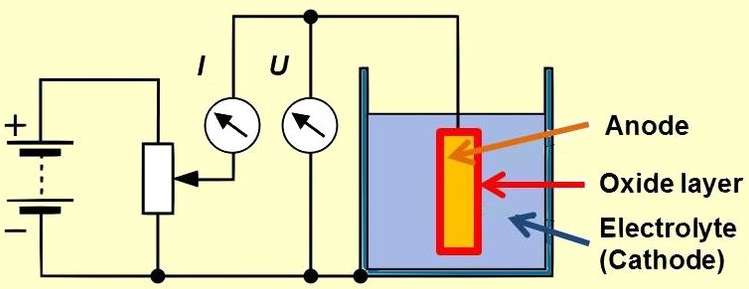

4. Anodic Oxidisation

This surface treatment is mainly used to treat light metals such as titanium and aluminium. Electrolysis is used to create oxide films, and these are naturally porous, so colouring agents and dyes are added to create a desired colour finish.

This process is very common for aluminium to prevent corrosion. There are also versions of this treatment that produce extremely hard and thick ceramic coatings on the part surface.

These are just four metal surface treatments to know, but they are all vital industrial processes.